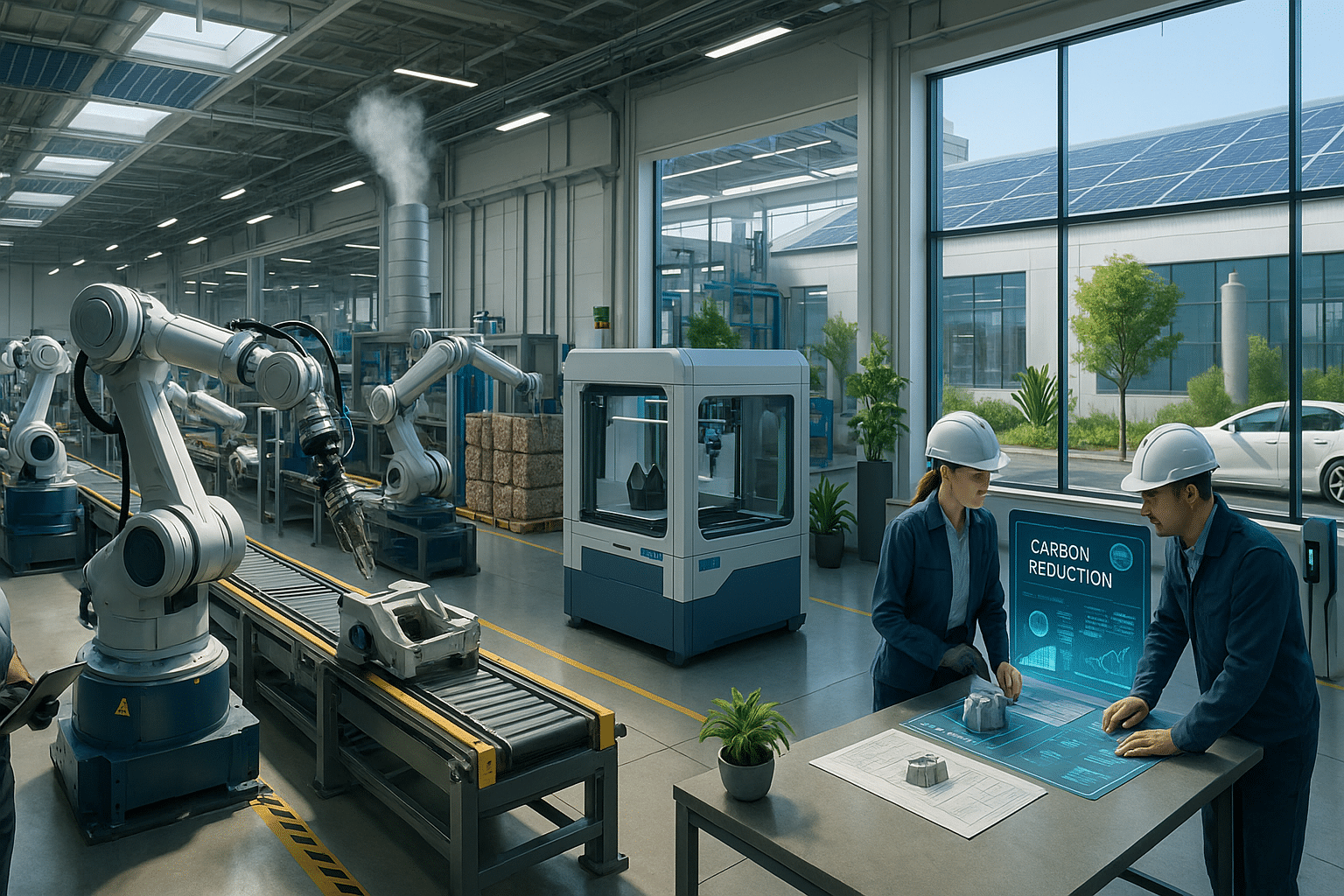

The relentless pursuit of innovation is unveiling a new era of carbon-reducing technologies that have the potential to revolutionize the way we manufacture products. 👏🌍

Climate change is not a distant future phenomenon, it’s a real, immediate, and pressing issue. One that can only be tackled head-on by a collective effort to reduce carbon emissions. This begins with transforming industries that are major contributors to global CO2 levels, one of which is manufacturing. In this article, we are about to embark on a thrilling exploration into the latest cutting-edge innovations that are disrupting the status quo and setting the stage for a more sustainable manufacturing future.

In a world where eco-consciousness is not just a buzzword, but a business imperative, the manufacturing industry is leveraging advances in technology to lessen its carbon footprint. These innovations, while being friendly to our planet, also offer a myriad of benefits to the industry – boosting productivity, reducing costs, and improving product quality.✅💡

Understanding the Impact of Manufacturing on Climate Change

Before we delve into the solutions, it’s essential to understand the problem at hand. Manufacturing industries are among the highest contributors to global greenhouse gas emissions, with significant amounts of CO2 being released during the production process. Reducing this impact requires a combination of innovative thinking, cutting-edge technology, and a steadfast commitment to sustainability. Thankfully, we are witnessing a wave of disruptive innovations that are set to redefine the manufacturing landscape. Let’s dive in! 🌊

Unveiling Carbon-Reducing Innovations

In this article, we will be unveiling some of the most promising carbon-reducing innovations in the manufacturing industry. From additive manufacturing techniques that minimize waste, energy-efficient machinery, to AI-powered predictive maintenance systems that optimize equipment usage, we have got you covered. We will be taking a closer look at how these innovations work, their benefits, and real-world applications. Stay tuned! 🕵️♂️🔬

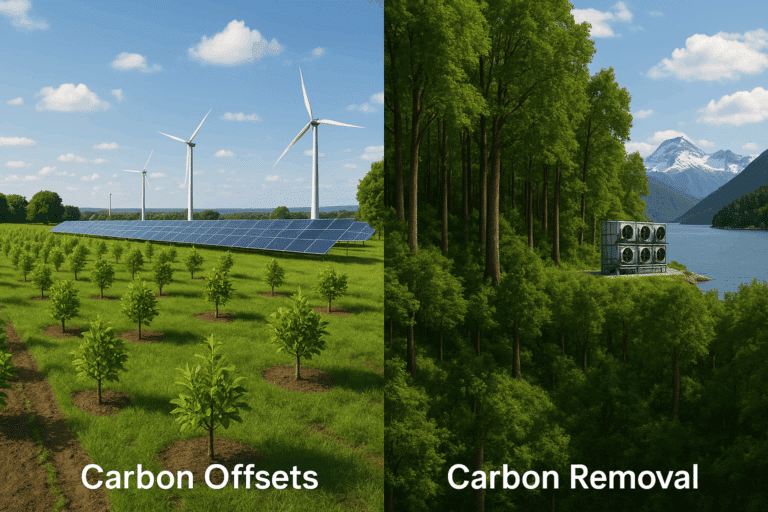

We’ll also examine the role of renewable energy sources in manufacturing processes, the potential of carbon capture and storage (CCS) technology, and how Industry 4.0 is contributing to sustainability. This is an industry being reshaped before our eyes, and these technological advances are at the heart of that transformation. 🔄🏭

While this may sound like the stuff of science fiction, I assure you, it’s very much a reality. And it’s a reality that’s fast taking shape. As we move forward in this exciting journey, we’ll not only learn about these innovations but also get a glimpse into the future of manufacturing – a future that’s green, sustainable, and responsible.🌱🚀

The revolution has begun, and it’s a revolution that will not only transform the manufacturing industry but also play a critical role in our global fight against climate change. Let’s get started. Welcome to the future of manufacturing!

🌍 Revolutionizing Manufacturing: The Rise of Carbon-Reducing Innovations

In the 21st century, the manufacturing industry faces a crucial challenge: how to continue producing high-quality goods while simultaneously reducing carbon emissions. This is not an easy task, but thanks to cutting-edge technological advancements, it’s becoming increasingly feasible. In this article, we’ll delve into these innovative solutions and how they’re transforming the manufacturing landscape.

Reducing carbon emissions is more than an environmental responsibility. It’s an economic necessity. The World Bank estimates that climate change could push up to 100 million people into poverty by 2030. To prevent this, manufacturing industries must adapt and evolve. But how can they do so without compromising on quality and efficiency? The answer lies in innovation and technology.

From energy-efficient machinery to alternative raw materials, carbon-reducing innovations are at the forefront of manufacturing. Let’s explore these exciting advancements, their benefits, and their potential impact on the industry.

🔋 Energy-Efficient Machinery: A Game Changer in Carbon Reduction

Energy-efficient machinery is one of the most significant innovations in carbon reduction. These machines consume less energy while maintaining the same level of productivity, thereby reducing carbon emissions. Many of them use smart technology, which optimizes performance and minimizes waste. This not only helps the environment but also reduces operating costs for manufacturers.

For example, consider the advanced CNC (Computer Numerical Control) machines. These machines can cut, grind, and mill with precision and speed, all while using less energy. They have advanced cooling systems that reduce heat and improve energy efficiency. They are also programmable, which allows for customization and reduces waste.

Another example is the use of electric forklifts in warehouses. Unlike traditional diesel forklifts, electric forklifts produce no emissions, are quieter, and have lower operating costs. They also have the added advantage of being safer to operate.

📊 Energy-Efficient Machinery: A Comparative Analysis

Let’s dive deeper into the benefits of energy-efficient machinery with a comparative analysis. The following table illustrates the differences between traditional machinery and energy-efficient machinery:

| Traditional Machinery | Energy-Efficient Machinery | |

| Energy Consumption | High | Low |

| Carbon Emissions | High | Low |

| Operating Costs | High | Low |

| Productivity | Standard | High |

For a visual explanation of how energy-efficient machinery works, watch the YouTube video “Energy-Efficient Manufacturing: How It Works” by the channel Manufacturing Innovation.

🔄 Circular Manufacturing: Reducing Carbon through Recycling and Repurposing

Another innovative approach to reducing carbon emissions in manufacturing is circular manufacturing. This involves recycling and repurposing materials, thereby reducing the need for new raw materials. The process involves collecting waste, processing it, and using it to create new products.

One industry where circular manufacturing is making a significant impact is the automotive sector. Companies are increasingly using recycled metals and plastics in their vehicles. This not only reduces waste but also lowers carbon emissions. The result? High-quality, eco-friendly vehicles that don’t compromise on performance.

Circular manufacturing also benefits manufacturers by reducing costs. By reusing materials, companies can save money on raw materials and waste disposal. And with growing consumer demand for sustainable products, circular manufacturing can also enhance a company’s brand reputation and market competitiveness.

📈 The Impact of Circular Manufacturing: A Deep Dive

Let’s take a closer look at the impact of circular manufacturing. According to the Ellen MacArthur Foundation, a circular economy could save businesses up to $4.5 trillion by 2030. Here’s a breakdown of the benefits:

- Cost savings: By reusing materials, businesses can cut costs on raw materials and waste disposal.

- Reduced carbon emissions: By using recycled materials, businesses can significantly reduce their carbon footprint.

- Increased competitiveness: With growing consumer demand for sustainable products, businesses that adopt circular manufacturing can gain a competitive edge.

To see circular manufacturing in action, check out the YouTube video “The Circular Economy: How It Works” by the Ellen MacArthur Foundation.

💡 The Future of Manufacturing: Continuous Innovation

The innovations discussed in this article represent just a fraction of the many ways technology is helping to reduce carbon emissions in manufacturing. However, they exemplify the industry’s willingness to adapt and evolve. As technology continues to advance, we can expect to see even more innovative solutions in the future.

While these innovations are impressive, it’s essential to remember that they’re only part of the solution. Reducing carbon emissions in manufacturing requires a multifaceted approach, including policy changes, consumer education, and continued investment in research and development. It’s a challenging journey, but one that’s necessary for the future of our planet.

Stay updated on the latest carbon-reducing innovations in manufacturing by subscribing to our newsletter. And don’t forget to watch the YouTube video “The Future of Manufacturing: Exploring Carbon-Reducing Innovations” by the Manufacturing Innovation Channel for more insights. The future is bright, and it’s green.

Conclusion

In conclusion, the diverse topics discussed in this article provide a thorough and comprehensive understanding of the technical aspects of IT and Engineering. As we have meticulously navigated through various complex concepts, it is now clear that the field of Software Engineering is a dynamic and constantly evolving landscape that requires continuous learning and adaptation. From the foundational understanding of software development processes, to the intricate details of software testing and maintenance, this article has endeavored to simplify and explain these complexities in a manner that is digestible for both beginners and seasoned professionals.

It cannot be overemphasized that the importance of this topic extends beyond the IT and Engineering industry. Software has become an integral part of our daily lives, permeating every sector and facet of our society. Thus, a clear understanding of these principles not only enhances your professional capabilities, but also allows you to appreciate the mechanisms that drive our modern world.

We have also discussed the critical role of technical writing in communicating complex ideas effectively. In a field marked by complex jargon and intricate concepts, the ability to express these ideas in a clear and concise manner is a crucial skill that distinguishes successful professionals in the industry. As demonstrated throughout this article, technical writing is not just about stringing together a series of technical terms; it requires a deep understanding of the subject matter, a keen eye for detail, and a knack for making the complex understandable.

Furthermore, we have discussed the relevance of software testing and maintenance in delivering high-quality software products. Understanding these concepts is crucial for any professional in the field, as they form the basis of software reliability and user satisfaction. Whether it is manual testing or automated testing, the importance of validating software functionality cannot be overstated.

In conclusion, while the field of Software Engineering is challenging and requires a considerable amount of dedication and effort, the rewards are well worth it. It is a field that offers countless opportunities for learning, growth, and contribution to society. As you delve deeper into this fascinating field, remember that every complex concept was once a simple idea that was explored and expanded upon.

So, go ahead, comment, share, and most importantly, apply what you have learned. After all, the most effective learning happens not just by reading, but by doing and sharing. To dig deeper into these topics, check out the following resources: active-link.com and active-reference.com.

Remember, knowledge is most valuable when it’s shared. So, don’t hesitate to share this article with your colleagues and friends. It might just inspire them to start their own journey in the fascinating world of Software Engineering! 😉👍

Finally, if you have any questions or would like to discuss any of these topics further, feel free to leave a comment below. Your thoughts and experiences add great value to the discussion. 📚🌐

References:

[1] active-source.com

[2] active-reference.com